Getting started...

Preliminary considerations

Foundation

A wooden floor does not have the strength needed to support the Roquetinho. A foundation is then a necessity. A connection with the nearest wall can be a solution. This works with a console (for example steel T-profiles inserted in the wall). Let only a professional do it!

Chimney

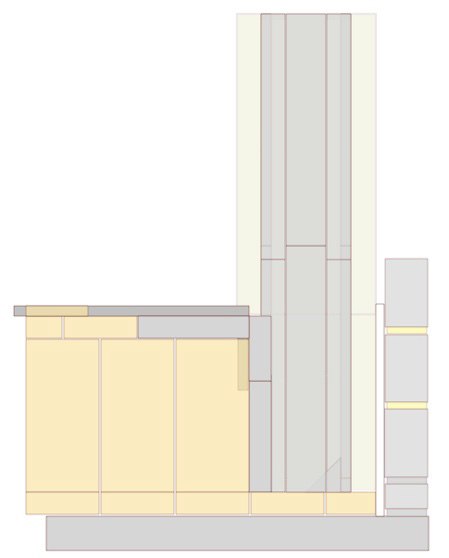

You need a chimney of at least 4 meter high, calculated from the stove bottom. Inside the room a singular inox tube of Ø 10 cm will do. Up from 30 cm under the ceiling and outside, the tube has to be double and insulated. Normal chimney rules are applicable such as having the top of the flue above of the roof.

Plinth

Once the foundation and the chimney are settled, the first next thing is the plinth. The stove bottom slab sits on this plinth. The plinth can be masonry, (concrete) bricks or any similar material of your choice. Height should be at least 10 cm, but 15 cm is better if you want an easier reach to the firebox. You can make it the same size as the stove's bottom slab, or a bit smaller (3-4 cm less).

Off-site prefabrication

This building description assumes that as much work as possible is done off-site, so as to minimise the time required on site. The preparatory (off-site) work consists of the following: making various special castings, laying the first two layers of the bell on the bottom slab, constructing the core, making the steel door and P-channel, and (possibly) cutting some of the special blocks and firebricks.

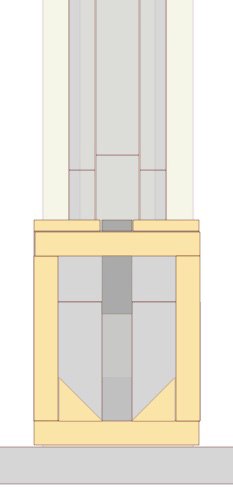

Front view

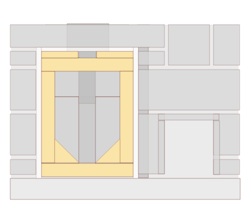

2. Partition and joining block

Lower bell construction

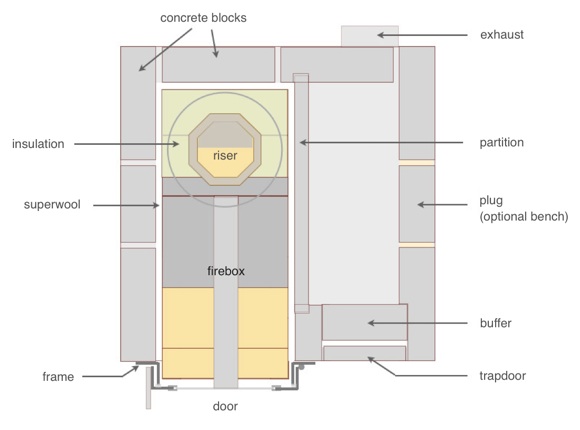

Third layer, partition and trapdoor opening

Lay the third layer of concrete blocks using cob. The concrete block with the slot must be laid accurately at the back to accept the partition.

Put in place a piece of superwool of 303 x 473 mm against the right side of the core. Lay the joining concrete block with mortar (1:5) and press it against the superwool. Now lay the trapdoor buffer block (including the M8 nut) using tile cement. Let this section harden for a while because it has to support some pressure when the stove is in use.

As soon as it is strong enough you can place the partition on a thin layer of cob. Slide the lower front of the partition into the joining block; the upper back of the partition is held in place by the block with the notch of 27 x 15 mm. Push the partition firmly against the superwool (use pressure laths) and fix it with mortar.

P-channel, fourth layer and the two lintels (worksheet 9)

Drop the p-channel into place. If good, it will fit easily through the slot in the firebox top casting and the cut out opening should be seen to be exactly in front of the port inside the firebox. At the front of the firebox it protrudes by 17 mm; once the metal door is in place this will fit into the door's 16 x 42 mm opening.

On each side of the p-channel at the front, glue the little lintel support firebricks. Place a piece of superwool 90 x 210 mm on the firebox top on each side of the p-channel. Carefully fill the space between the p-channel and the riser with superwool (important!). Finally, lay a larger piece of superwool measuring 322 x 242 mm over the whole firebox, covering the p-channel.

On the right side, fit the bench plug into place with some cob.

Lay the trapdoor lintel using mortar.

Now the fourth layer concrete blocks are laid. There is a special block with a cutout of 72 x 64 mm, the door lintel support, on the left. The door lintel rests on this. A second similar door lintel support block goes on the right side. Put the lintel in place with cob and press it firmly into the superwool: the joint between the firebox and the lintel must be airtight.

Insulating the riser

Insulating lower riser with vermiculite (worksheet 10)

To insulate the lower riser, the space around it (between the riser and the concrete blocks of the bell and the partition is filled with vermiculite that has been mixed with clay (mix 1 part dry clay powder : 5 parts vermiculite; then add 1 part water and mix again). Before filling, place a piece of superwool against the rear concrete blocks (behind the riser). Then carefully fill the space with the vermiculite mix, paying particular attention to the crevices between port and riser.

Upper riser and fracture point

The upper part of the riser can now be placed onto the bottom part. Use a small amount of clay between the upper and lower parts instead of glue, creating a fracture point. Because of the extreme temperatures, the two parts will expand at slightly different rates, and this fracture point prevents the upper part of the riser from cracking.

Insulating the upper riser

Lower the 200 mm diameter steel tube over the riser until it rests on the firebox top and the vermiculite fill. Fill the space between tube and riser with the vermiculite/clay mix.

Building up the rest of the bell it is best to have some kind of guides. One method is to clamp laths to the four corners at the bottom slab; mark them with the layer heights (which are height of the concrete blocks + 9 mm joint for layers 5 to 7 and height of the firebricks + 7 mm joint for layers 8 to 11). Use spacers to bring the laths 2 mm away from the bell and level the laths carefully. String can be used between the laths to get each layer exactly level.

Lay the concrete blocks for layers 5 to 7 using cob.

Laying masonry with cob is really different from making it with cement. Do some tests first; the cob shouldn't be too dry or too wet. First put a "roll" of cob on the previous layer and press the blocks down onto it. Once the whole layer of blocks is in place, fill in the vertical joints. There must be no gaps!

The 8th layer is the first one with firebricks (normally 220 x 106 x 60 mm). There's a bit more cutting work here, these since dimensions are different from the concrete blocks. Lay the firebricks for layers 8 to 11 using cob.

In the upper layer, a 15 x 30 mm notch must be cut in each block. This will accept the steel top.

The steel top

If you use the 60 mm thick firebricks the notch on top of the stove will be 490 x 490 mm. To have a margin of 7,5 mm, the steel top is then 475 x 475 mm.

Put the plate on strips of superwool. The margin is filled up with 8 mm fire cord.

Frame and door unit (worksheets: Frame&Door)

The worksheets for the frame and door unit assume a firebox with outside dimensions of

220 mm (w) x 284 mm (h). Most likely the outside dimensions of your firebox will differ. You will have to adapt the blue figures in the worksheets.

Study all worksheets before you start making the frame and door unit. Once it’s finished you place it in such a way the p-channel fits exactly in the door's opening. Outline the exact place of the holes, drill these, put in plugs and fasten the frame with inox screws.

1. Notch for lintel

3. Plug for optional bench

4. Slot for partition

lintels

Before getting started with the stove it is important to check a few things: the supporting floor needs to be strong enough, the chimney should be okay, and volume and insulation of the space to be heated should be in such a way the Roquetinho can do the job.

As much as possible the stove should be in the centre since it is mainly a radiation heater. Further: the ventilation of the room has to be sufficient. There's no need for a separate air supply.

Materials list

• Solid refractory concrete

• Insulating refractory concrete (for riser castings)

• Firebricks (220 x 106 x 32 mm)

• Refractory glue (Moviset)

• Portland cement (cimento)

• Tile cement (cimento cola)

• Builder’s sand (areia grossa)

• Gravel

• Clay powder and fine sand

• Concrete blocks (198 x 98 x 62 mm)

• Superwool 100x61 cm

• Vermiculite

• Stainless steel tube for flue outlet (∅100 mm x 60

mm)• Steel tube for upper riser insulation (∅200 mm x

425 mm)• Rectangular-section steel tube for P-channel

(40 x 15 x 2 mm)

Various materials for temporary works – such as a transport board, various laths and battens, etc.

Roquetinho is…

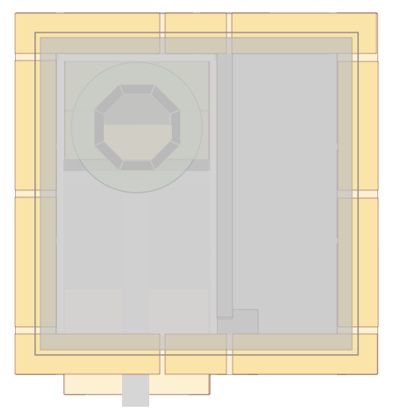

Structurally, the Roquetinho stove consists of a brickwork ‘bell’ that absorbs and stores heat, within which is a rocket burner, consisting of a firebox and a riser for the hot gases. The bell stands on a plinth laid on the foundation floor. The bell consists of 11 layers: seven lower layers of concrete blocks and four upper ones of firebricks.

Roquetinho is best constructed by prefabricating the rocket core and the lower section of the bell offsite. The first site work is construction of the plinth. The lower section of the bell is set on the plinth and the core fitted into the bell. Then the bell is completed on-site, before completion of the stove with the metalwork.

To accompany this text there are worksheets, the first one is a building overview.

List of special castings

Insulating refractory concrete

Riser castings (16)

Riser heel

Solid refractory concrete

Port

Top of fire box

Normal concrete

Bottom slab

Door lintel

Partition

Trapdoor lintel

Trapdoor

Bench plug

Flue exit

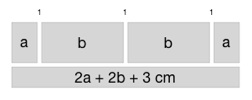

If the bricks used have different dimensions, adapt the measure-

ments of the bottom slab. For example, if the bricks are 210 x 105 x 60 mm, the sides of the bottom slab will be 57 cm instead of 55 cm. In that case you make the bottom slab 57 x 57 cm. This building description assumes use of the Portuguese bricks and thus a bottom slab of 55 x 55 cm. This is the minimum bottom slab size that works for the Roquetinho.

The stove, seen from above

Lower section of bell

Preparing the bottom slab

Place the cast bottom slab in a suitable place for working. It must be level.

First two layers of bell blockwork (worksheet 4)

Construct the first two layers of concrete blocks on the bottom slab. Use mortar with cement: sand in proportions 1:5. Take care to control the dimensions (height per layer is 98 mm + 9 mm joint) and make sure the structure is square and level. In order to get the lintel over the door in the right place, the first layer has a height of 37 mm, so the bricks need to be cut.

Note:

As part of the first layer, put in a piece of Ø 10 cm stainless steel tube (6 cm long) with a female end outward. Cut and lay blocks to incorporate this tube as shown in the diagrams. This forms the exhaust of the stove. The front-right blocks (layers 1 and 2) are notched to 15 x 35 mm to hold the trapdoor; these are laid using tile cement. On the right side there is a square opening for an optional heated bench. This is closed temporarily by a plug, which is fixed in place using cob instead of cement.

This lower part of the bell is now ready for transport to the site.

Preparing the trapdoor buffer (worksheet 5)

This building description assumes that the core is built off-site for transport to the final installation location. The core is built up on a transport board that must be sturdy enough to carry its weight. A sheet of 18 mm melamine-coated chipboard or similar works well.

Place a pair of battens parallel on the transport board and lay a couple of the bottom firebricks in place between them to get the correct spacing. Fix the battens lengthwise on the transport board. This structure will hold the bottom firebricks in place during the build.

Construction work is easiest if the transport board can be placed on a workbench or raised to a similar height.

(An alternative method is to construct the core in-situ on top of the bottom slab.)

About glueing with Moviset

Spread the glue over the surfaces to be glued: both surfaces need to be covered completely (not thick, only ± 0,5 mm). There must be no air spaces when the surfaces come together.

Moviset sets within 24 hours when the temperature is 15°C or above. At lower temperatures, setting time is not yet known, but it may be much slower.

Bottom firebricks and firebox (worksheet 6 )

You will need four full firebricks and one cut firebrick for the bottom of the core. This building description assumes firebricks with measurements 220 x 106 x 32 mm.

Butter one edge of the first firebrick with Moviset and lay it on the transport board. Butter two edges of the next three bricks and lay them in place. Carefully apply pressure across the four firebricks until the Moviset begins to squeeze out. A large clamp helps with the application of a little pressure. Now measure for cutting of the fifth firebrick; the total length of the core base must be 506 mm. Cut the final brick to achieve this total length (remembering to take account of the 1 mm of Moviset). Make sure the bottom bricks are level and let dry for a short time.

Glue the walls of the core onto the base: three firebricks placed vertically for the left, three for the right side. Try to make sure the firebricks that will be visible at the front of the core are all flush; this is simply an aesthetic consideration. Allow to harden for a short time.

Next glue on the firebox top, which consists of one casting with a slot for the p-channel to pass through, one whole firebrick, and one firebrick cut to size such that the front of the firebox is flush. The slot for the p-channel may need to be filed slightly round to accept the corner weld on the p-channel; the p-channel should sit completely flat on the firebox top. The part-firebrick goes at the front with cut face inwards to ensure that top joints are offset from the wall joints (for added strength) and to preserve the aesthetics of the front. (Remember that the front edge of the firebox is visible to the end user when the Roquetinho door is opened.)

Finally, form the port at the rear of the core. Glue the two vertical port castings and then the lintel casting across the top. Careful measurement is necessary here. Most important is that all of the rear port castings are perfectly vertical and aligned so that they form a flush surface (for later installation of the riser). The top of the port lintel should be level. The port opening must be 40 mm wide.

The 45º chamfered bottom bricks can then be glued into the firebox, ensuring that all gaps are filled with Moviset.

Riser (worksheet 7 )

Cut two riser castings to the same height as the port, less one mm to account for the Moviset. This height should be around 253.5 mm, but it should be measured. Best is to mark a pencil line at the exact height, then use a grinder to cut along the line such that the pencil mark just disappears; this will give the 1 mm allowance for the Moviset.

Each of these cut riser castings can then be glued with Moviset to two others using a 135° lath to set the correct angle (as shown in the picture). Leave these assemblies to harden for a while, then glue them to the firebox port. The tops of the cut riser castings must be flush with the top of the firebox port lintel. Now, before closing the riser with the final casting, the heel must be fixed in place at the bottom of the riser with some glue, filling up (completely!) the space underneath it with cob or glue. Ensure the correct position/angle by inserting a lath cut with a 45° end into the port through the firebox. Now close the back of the riser with the final riser casting using Moviset.

Three short sections of riser casting sit on the port lintel to complete the lower riser. It is important that the inner face of the middle casting is flush with the rear of the port lintel to ensure a smooth interior finish to the riser. Also take care that these small pieces are not too tight. If necessary, cut away a fraction until they make a loose fit (with space for the 1 mm of glue). Adjust all angles and ensure the riser is symmetrical, vertical, and sealed all around while the Moviset remains workable.

Now leave the core assembly to set hard before transporting it to site. At this point you can already glue the upper riser together. Like the bottom part, half of the castings are 350 mm of length, the other half 330 mm. Making it this way, the upper part will fit exactly in the bottom part.

On-site construction

Once on site, determine the location of the Roquetinho. The rear edge of the bottom slab should be placed at least 160 mm from the rear wall (to allow space for connecting the flue). Mark the footprint of the plinth on the floor according to the chosen overhang. Note well when aligning the plinth that the flue does not exit in the centre of the Roquetinho. The floor can be protected by sticking lengths of masking tape 10 mm outside this footprint.

Installing the lower section of the bell

Construct the plinth using concrete blocks and normal mortar. Ensure it is square and level. Butter the top face of the plinth with an even layer of mortar and lower the bottom slab onto it. Positioning is made easier if two concrete blocks (standing on end) are placed on the floor so as to mark the locations of the two rear corners. Tap the bottom slab down gently so that it settles into place firmly (and level) on the mortar.

Installing the core (worksheet 8)

Remove the battens from the transport board. Carefully slide a pair of lightweight winching straps under the core to use as lifting handles; this is best done by sliding the core slightly off the end of the transport board and lifting it up a few degrees, making sure to take the weight on the middle of the bottom.

Use a few concrete blocks to form a platform in front of the bottom slab. Lift the core, still on the transport board, onto this platform. Ideally the core will now be at almost its installed height.

Prepare some cob and spread it in three lines 3 mm thick from front to back of the bottom slab where the core will be placed. The two outer lines will go under the sides. When the core is settled onto this cob, it will spread slightly. It is important that there are no sealed air pockets; air should be able to escape forward between the lines of cob.

Gently lift the core using the straps. Two people are needed to do this, with a third to ensure proper positioning of the core on the bottom slab. Lower the core such that there is a gap of 12 mm to the left wall of the bell; this space will be filled with superwool. The front of the core protrudes exactly 30 mm in front of the bottom slab.

Ensure that the core settles into place level and without going out of position. It can be tapped gently with a rubber mallet. Fill the 12 mm gap with superwool. At the front it needs to be as airtight as possible.

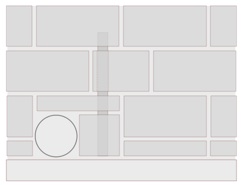

Side view

List of cut concrete blocks and firebricks

Concrete blocks

Blocks for first layer of bell (height = 37 mm)

Joining block (left side of trapdoor)

Block with slot for rear of partition

First-layer block for right side of trapdoor

Second-layer block for right side of trapdoor

Trapdoor buffer

Fourth-layer door lintel support, left

Fourth-layer door lintel support, right

Firebricks

Door lintel support firebricks

To cast the bottom slab, make a 50 mm-high mould in which you pour the concrete. Proportions of the concrete are 1 cement : 2 sand : 3 gravel. In three days it will be hard enough to de-mould. As with any concrete, the casting must remain humid for the first few days (concrete reaches full strength only after 28 days). Apart from the bottom slab there are five other concrete parts to be cast; you'll find them on worksheet 2.

Cut concrete blocks and firebricks

Many cut blocks and firebricks are needed, mostly to complete the normal masonry. Blocks also have to be cut for the flue opening, etc. There are also a number of rather special cut blocks and firebricks, as listed at the right. Marking templates may be useful for setting out cut lines on these pieces.

Building description (2018)

by Roelof Groenenboom and Steve Cassidy

Making the moulds

It's practical to use plastic coated chipboards as a bottom for the moulds, since they are already waterproof and don't need to be painted. Saw the laths that form the mould and fix them on the bottom with screws (not with glue). Paint the laths (2 layers). When the paint has dried, fill the inside brims with a bit of acrylic sealant. If you re-use the mould, clean it well and seal the brims again. Dimensions for the normal concrete moulds are on worksheet 2, those for the refractory castings are on worksheet 3.

Vibration table

To cast forms out of refractory concrete you need a (simple) vibration table. As soon as the concrete mixture goes into the mould, it needs to be vibrated to condense the material and force the air bubbles out.

Here's a simple vibration table that you can put on a Workmate. A thick plywood board of 40x60 cm is attached to two 40 cm beams by four springs that you fasten with bolds and nuts. A 60 cm beam, fixed onto the two 40 cm beams, is clambed in the workmate. To stabilise the workmate, you put 2 concrete tiles on it. You shake the table using a hammerdrill, hitting a thick metal plate. On the top board you fasten the mould with clambs. Make sure the mould is level.

For a more regular use it's easier to have a motor attached to the table. In the video here below a motor is attached to the top board. An excentric weight has been fixed to the axle of it. There's an infinite diversity of designs that you can use, a lot of them are on YouTube.

Handling the fire concrete

Working with fire concrete is very different from working with normal concrete. Things like temperature, amount of water to be added and the open time for handling come very exact. Mixing and vibrating are skills to be learned by experience; if you do this for the first time consider your first castings to be try-outs.

Temperature

To process the material well, the concrete as well as the water to be added need to have a temperature between 10 - 20º Celsius. The very minimum is 7ºC. Exceeding 20ºC the hardening process will be substantially faster. There may be too little time then to process the mixture well.

Water

Use good quality drinking water of 10º - 20º C temperature. From the product information sheet, calculate the exact amount of water to be added. Note that this can be very different per product! E.g. for CaldeCast StrongLite you need ±225 ml/kg, but for Calderys F50 it's only 115 ml/kg. Do not exceed the maximum amount as indicated on the product sheet.

Mould

Before putting the concrete into the mould, the inside of the mould needs to be thoroughly greased with oil, otherwise the concrete would be fixed to the mould after hardening.

Mixing

Definitely use a dust mask to prevent breathing cement dust. Generally the concrete is shipped in sacs as a dry mix, needing only water to be added. Weigh the amount of concrete you need and put it in a bowl. Add the measured amount of water and mix thoroughly with a trowel. Mixing time shouldn't exceed 3 minutes. You now have an earth-humid material that immediately needs to be shoveled into the mould.

Applying

Fill up the mould and switch on the vibration table's motor. After some minutes of shaking the concrete will get more fluid and air bubbles will move out. With a filling-knife, push the concrete into the corners. If needed, add more concrete into the mould. Vibrating time shouldn't be too short, but certainly not too long: that would cause demixing. Water on top of the mixture is an indication of demixing. This should be prevented.

Hardening

The concrete hardens by a chemical reaction between the aluminium cement and the water. This may produce heat. Directly after vibrating, cover the mould with a piece of plastic to prevent evaporation of the water. At 15 - 20ºC, hardening will take about 6 -8 hours. 80% of its strength is then attained (after ± 2 weeks the concrete has fully completed hardening). At lower temperatures of working space and/or material hardening will take longer. Before de-moulding check if the concrete has hardened well. To de-mould, take off one side of the mould and tap the form out.

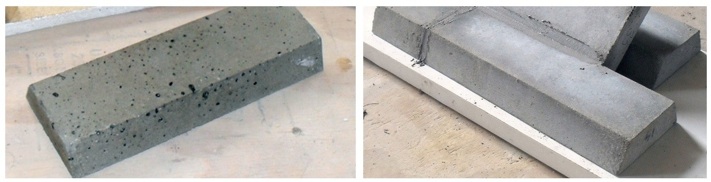

too much airbubbles

how it should be

In this description you can learn step-by-step how to make your own Roquetinho. All you need is some basic do-it-yourself skills, and for making the door (someone with) welding skills. Materials costs will be less than

€ 200,-; if you build in series it can even be as low as € 125,- per stove (Portugal, 2018).

© 2018 roquetinho.eu

© 2018 roquetinho.eu. This building description is available under the Creative Commons Attribution-ShareAlike 4.0 International license.