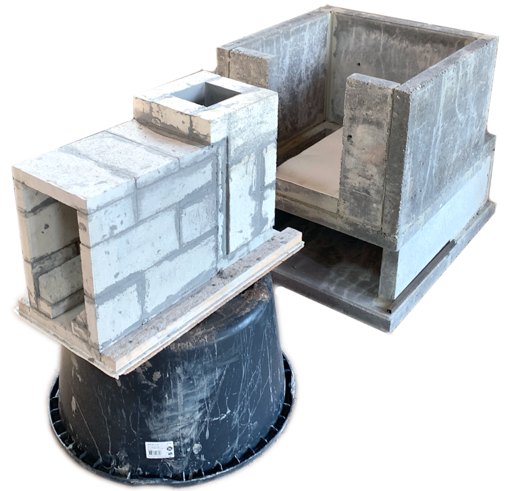

Step 4 First layer of the bell. Placing the core

Bell: the first layer

The top of the firebox should be exactly level with the first layer of the bell. In the SketchUp drawing, that first layer is 400 mm. The firebox is 348 mm, with underneath a 50 mm high tile and a 2 mm high layer of ceramic felt.

The side walls of the first layer are two full tiles of 400 x 600 mm. The back wall has 50 mm sawn off on both short sides (as shown in the photo of the diamond circular saw, see Step 2). In this wall, at 160 mm from the top and 113 mm from the sides, you drill two holes of Ø 8 mm and approximately 25 mm deep.

At the front, there are two tiles of 400 x 130 mm. Here too, you drill a hole of Ø 8 mm, at 160 mm from the top and 113 mm from the sides. These ones are drilled all the way through. Drill from the front and back (fig 1).

Now glue the left tile and the back tile in place. The rough side of the tiles is on the outside. Use clamps again to press the parts together. Make sure it is flat, square, level and at the same height.

Then glue the right tile and the two front tiles in place.

Finally, glue a 548 x 240 x 50 mm tile to the bottom.

The glue of the core must be fully hardened: let it dry for at least 3 days before lifting it into place. The tiles of the first layer must also have had time to harden thoroughly.

Place a piece of ceramic felt measuring 540 x 220 x 2 mm on the bottom tile. Secure it with a few dabs of glue so it does not shift (fig 2).

Then place the transport board with the core as close as possible to the stove, preferably on an elevation of concrete blocks or something similar. Remove the battens from the transport board. In two places you pull a strap under the bottom of the core, and with two people you carefully lift the core onto the ceramic felt with these straps. See the photos above.

The front must be flush with the front of the bell. Check with a level, a square and a tape measure whether everything is in the right place.

Once everything is in order, you fill the gaps on either side of the core with two strips of Superwool. First press them flat so that they can easily be pushed into the opening (fig 3). Finally, on top of the firebox you place a 50 mm wide strip of Superwool.

Retaining plates

Place a piece of Superwool onto both walls of the firebox, and against it a steel plate of 300 x 345 x 4 mm. These plates rest on two nails, which you have inserted into the ceramic felt.

In the drilled holes, you put a threaded rod of Ø 8 mm and 550 mm long, which you insert through a square tube of 15 x 15 x 490 mm. The plates are held in place with wedges (fig 4).

1.

3.

ceramic felt

bottom tile

2.

4.

rod

wedge

nail

tube 15x15 mm