Working with fire concrete

Vibration table

To cast forms out of refractory concrete, you need a (simple) vibration table. As soon as the concrete mixture goes into the mould, it must be vibrated to compact the material and force the air bubbles out.

Here you see a simple vibration table that you can put on a Workmate. A thick plywood board of 40x60 cm is attached to two 40 cm beams by four springs that you fasten with nuts and bolts. A 60 cm beam, attached to the two 40 cm beams, is clamped into the workmate. To stabilize the workmate you place 2 concrete tiles on it. On the side of the plywood plate you fix a thick metal plate, against which you hold the hammerdrill to vibrate. Fasten the mould to the top board with clamps. Make sure it is level.

Vibration is much easier when using a vibration motor. The firecrete mixture only has a short open time, so it saves a lot of stress if you don't have to shake it by hand. A simple 50 watt vibration motor is sufficient for this purpose. You screw it to the bottom of the vibrating plate, see the picture. Also see this YouTube video.

Working with fire concrete is very different from working with normal concrete. Things like temperature, amount of water to be added and the open time for handling come very exact. Mixing and vibrating are skills to be learned by experience; if you are doing this for the first time it's wise to try it out with a small amount first.

Temperature

To process the material well, the concrete as well as the water to be added need to have a temperature between 10 - 20º Celsius. The very minimum is 7ºC. Exceeding 20ºC the curing process will be substantially faster. There may be too little time then to process the mixture well.

Water

Use good quality drinking water of 10º - 20º C temperature. From the product information sheet, calculate the exact amount of water to be added. Note that this can be very different per product! Do not exceed the maximum amount as indicated on the product sheet.

Mould

Before putting the concrete into the mould, the inside of the mould needs to be thoroughly greased with oil, otherwise the concrete would be fixed to the mould after curing.

Mixing

Definitely use a dust mask to prevent breathing cement dust. Generally the concrete is shipped in sacs as a dry mix, needing only water to be added. For the bell of the Roquetinho you can very well use home-mixed fire concrete: one part aluminum cement to three parts chamotte granules.

Weigh the amount of concrete you need and put it in a bowl. Add the measured amount of water and mix thoroughly with a trowel. Mixing time shouldn't exceed 3 minutes. You now have an earth-humid material that immediately needs to be shoveled into the mould.

Applying

Fill up the mould and start vibrating. After some minutes of shaking the concrete will get more fluid and air bubbles will move out. With a putty knife, push the concrete into the corners. If needed, add more concrete into the mould. Vibrating time shouldn't be too short, but certainly not too long: that would cause demixing. Water on top of the mixture is an indication of demixing. This should be prevented.

Hardening

The concrete hardens by a chemical reaction between the aluminium cement and the water. This may produce heat. Directly after vibrating, cover the mould with a piece of plastic to prevent evaporation of the water. At 15 - 20ºC, hardening will take about

6 -8 hours. 80% of its strength is then attained (after ± 2 weeks the concrete has fully completed hardening). At lower temperatures of working space and/or material hardening will take longer. Before demoulding check if the concrete has hardened well. To demould, take off one side of the mould and tap the form out.

As mentioned, it is definitely wise to first do a test with a small amount of fire concrete. Also because of the high purchase price of fire concrete, it would be a shame if a large form failed.

It’s a matter of trying it out to find the right quantities and proportions. Too much water results in reduced quality of the fire concrete, too little makes vibration very difficult. As an indication for the above moulds: for the longer parts 10 kg (2.5 kg aluminum cement on 7.5 kg chamotte) with 1.7 liters of water, and for the shorter parts 8.3 kg (2 kg aluminum cement on 6.3 kg chamotte) with 1.4 liters of water.

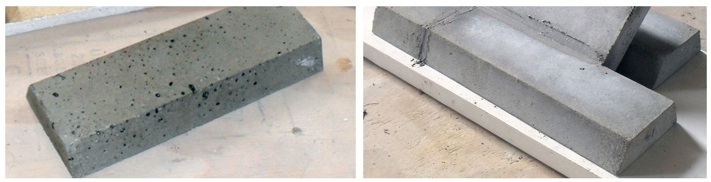

too much airbubbles

this is okay

Two moulds for fire concrete parts